Products Description

Description of new type organic fertilizer granulator

Dry materials are agglomerated into dense and hard blocks (cakes) under pressure, which is called the extrusion process; the cakes are crushed and screened to become granules, which is called the granulation process. The role of extrusion is to expel the air between particles and to make the distance between particles close enough to generate attractive forces such as van der Waals force, adsorption force, crystal bridge and embedded connection.

The particles of extrusion granulation are mainly formed by the force between molecules. The material is forced to pass through the gap between two relatively rotating rollers and compressed into strips, sheets, oblate spheres and other special shapes required by customers. Then, the sheet-like materials extruded by rollers are turned into granular materials that meet the use requirements through crushing and granulation.

Products parameter

| Model |

100model |

200model |

|

Output(t/h) |

1~1.5 |

1.5~2.5 |

|

Power |

15KW |

18.5KW |

| Press wheel specification |

150x220mm |

150X300mm |

| Feed size |

0.5mm |

0.5mm |

| Finished product specification |

2.5mm~10mm |

2.5mm~10mm |

| Reducer model |

MJ350 |

MJ400 |

| Material moisture |

2~5% |

2~5% |

Products picture

Products feature

◆No need for any additives, dry powder is directly granulated.

◆The particle strength can be adjusted to control the strength of the finished product.

◆The material is compressed and formed by mechanical pressure, without any additives, and the purity of the product is guaranteed.

◆Dry powder is directly granulated, without the need for subsequent drying process, which is more conducive to the connection and transformation of the existing production process.

◆The particle strength is high, and the increase in bulk density is more significant than other granulation methods, especially suitable for occasions where the bulk density of the product is increased.

◆It can control environmental pollution, reduce powder waste and packaging costs, and improve product transportation capacity.

◆The main transmission parts are made of alloy materials. Stainless steel, titanium, chromium and other surface alloys have greatly improved the wear resistance, corrosion resistance, high temperature resistance and pressure resistance, making the machine have a long service life.

company information

Henan Bolong Environmental Protection Equipment Co., Ltd. is located in Henan Province,China .We have More than 20 years on manufacture and selling the fermentation tanks .Our company designs and manufactures livestock and poultry waste harmless treatment equipment based on different organic content of livestock and poultry manure , learning from similar equipment at home and abroad through improvement of our technology , so that our fermentation tank can deal with different manure , livestock and poultry carcasses and can work in high humidity , extremely cold and other different areas .

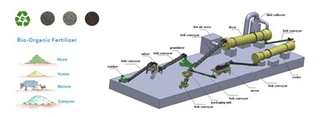

Products Application

Livestock and poultry manure, Agricultural waste, Seedling substrate, Fertilizer processing, Food waste, Municipal sludge

Hot Tags: new type organic fertilizer granulator, China new type organic fertilizer granulator manufacturers